Industrialised Fans

Introduction

This article takes an in astuteness consider business enterprise fans and their uses.

You bequeath larn:

- What is an industrial winnow?

- Types of industrial fans

- Uses for industrial fans

- Industrial fan design

- And much more…

Chapter One - What is an Industrial Fan?

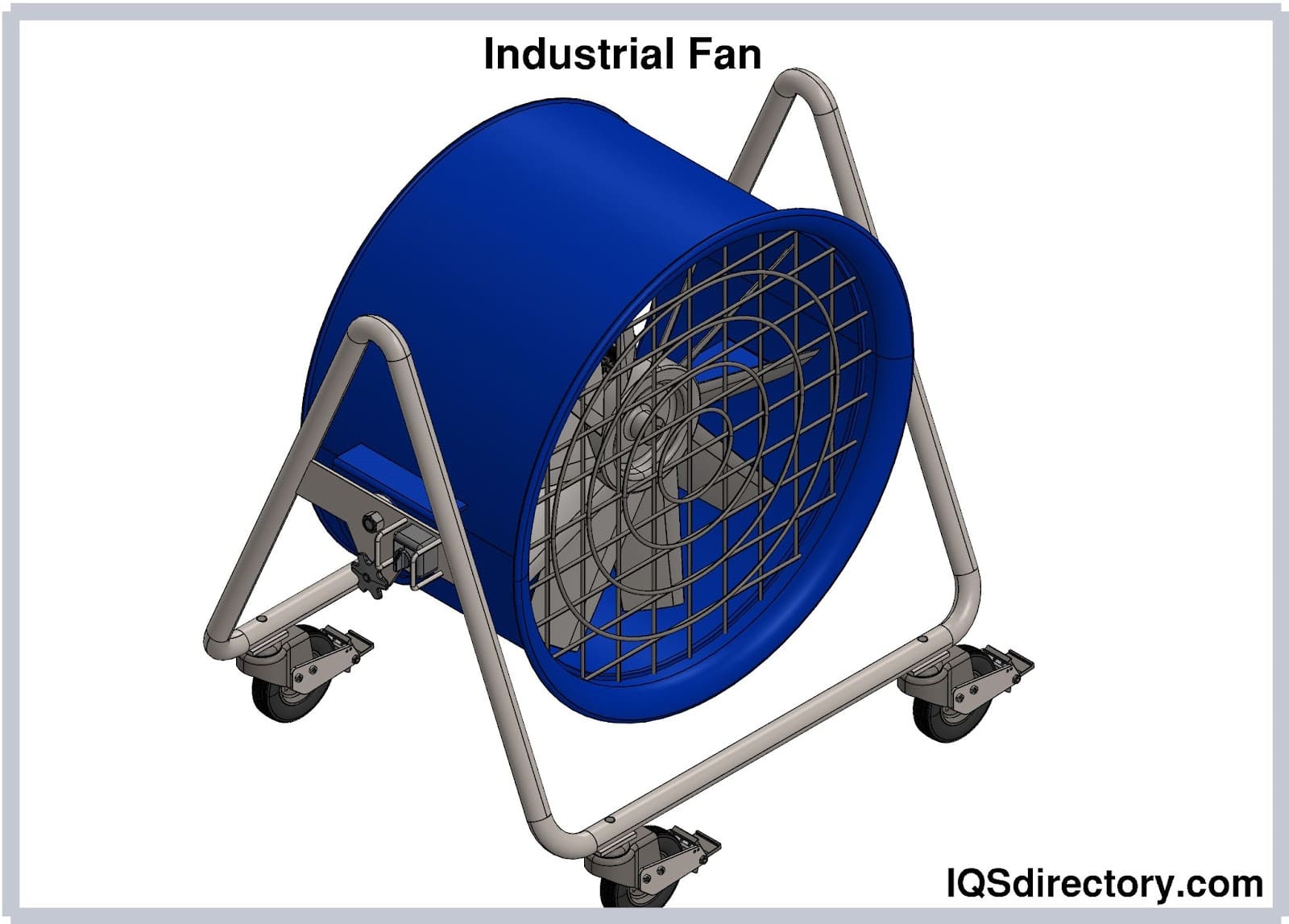

An industrial fan is a highly efficient, heavy duty ventilate flow device that is constructed from exceptionally durable materials and components to withstand demanding environments and operate longer to provide invariable flow of air and pressure. The strength of industrial fans is ascribable the materials accustomed construct them, which admit testicle or roller bearings, continuous welds, and housings made of regurgitate aluminum and stainless nerve.

There is a wide range of uses of industrial fans, from cooling large commercial buildings to providing cooling system for technical assembly operations. Regardless of the size up of the workspace, flow of air and circulation are critical to the health of workers and the efficiency of an application.

Chapter Two - Types of Industrial Fans

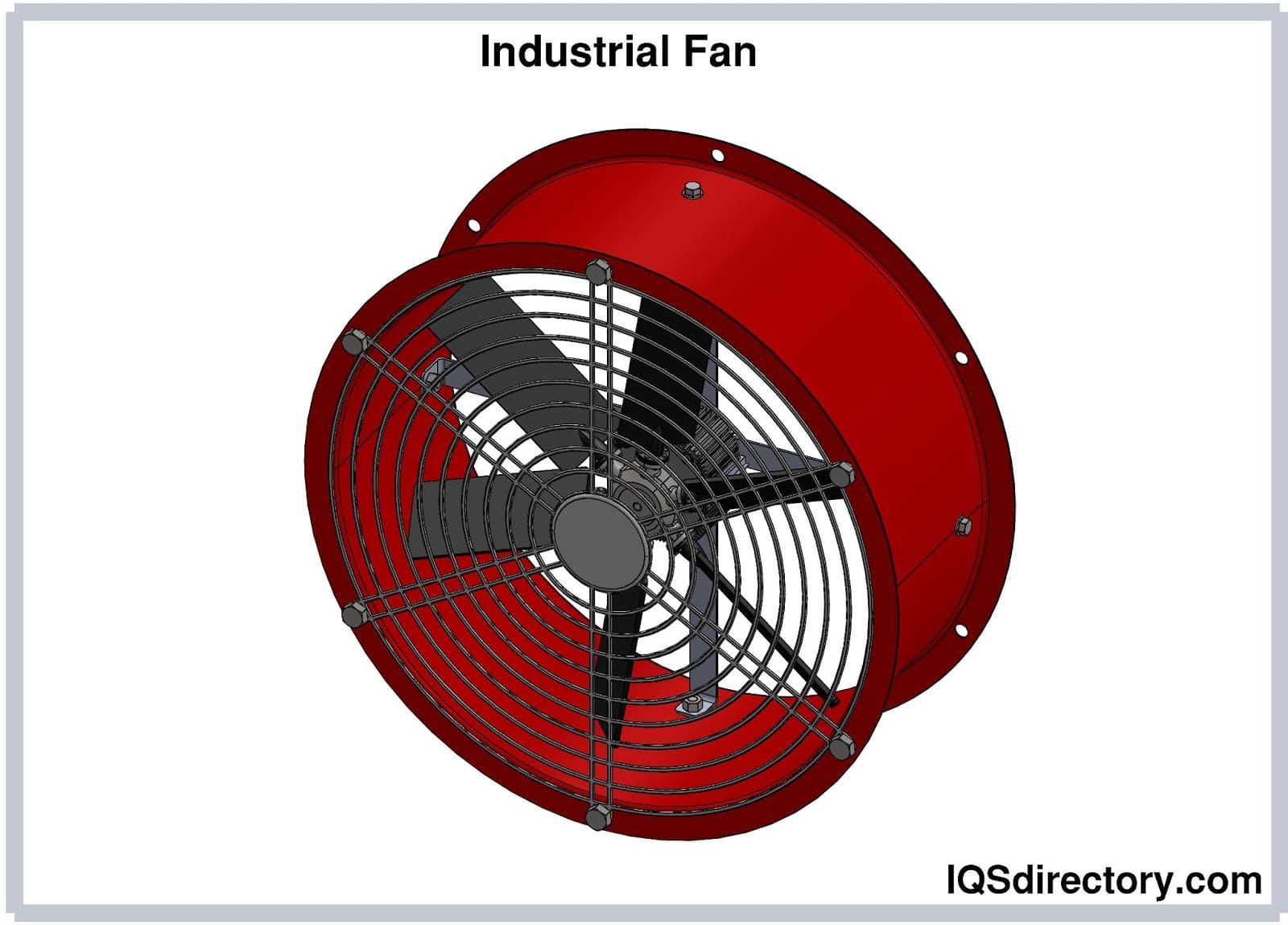

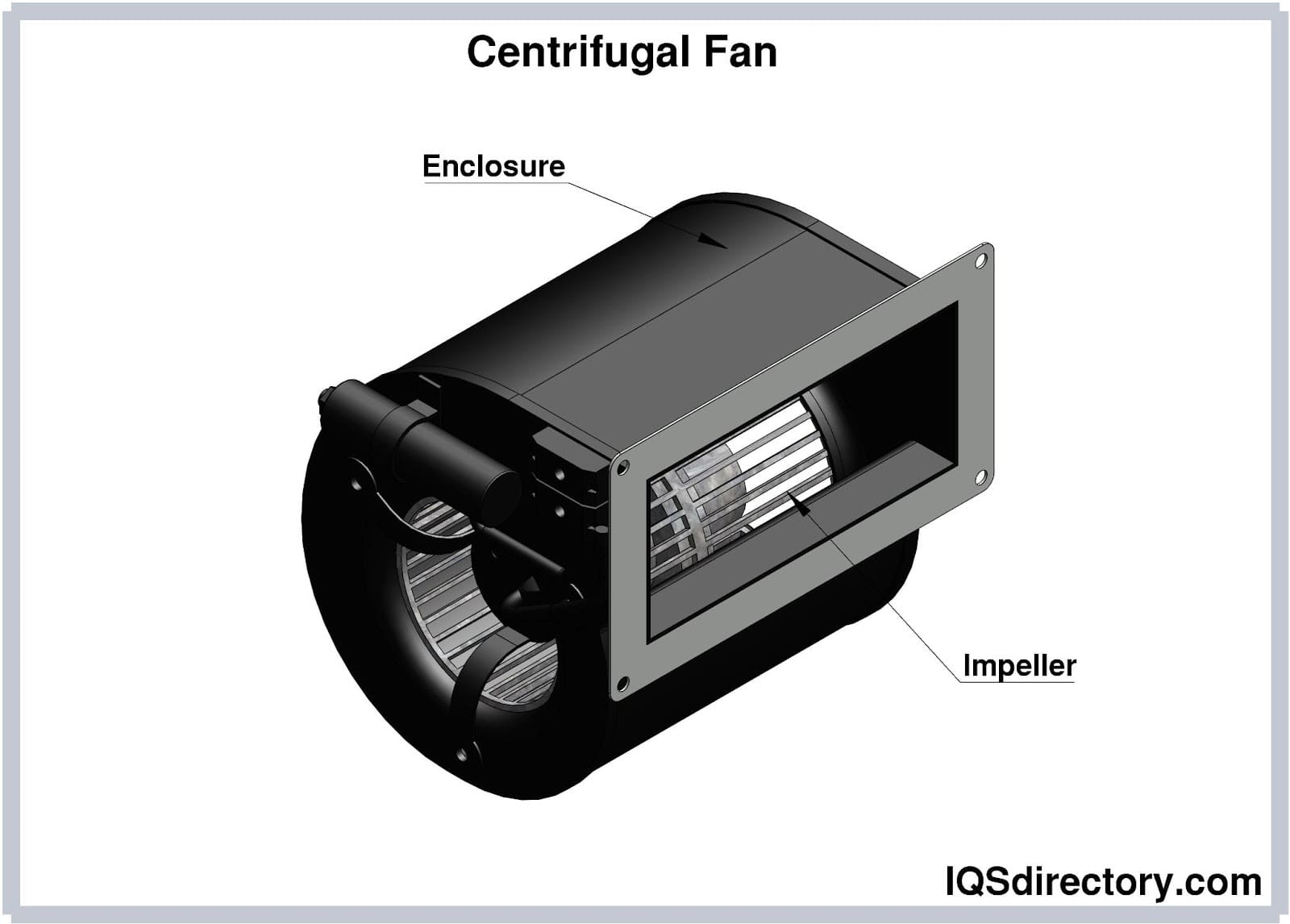

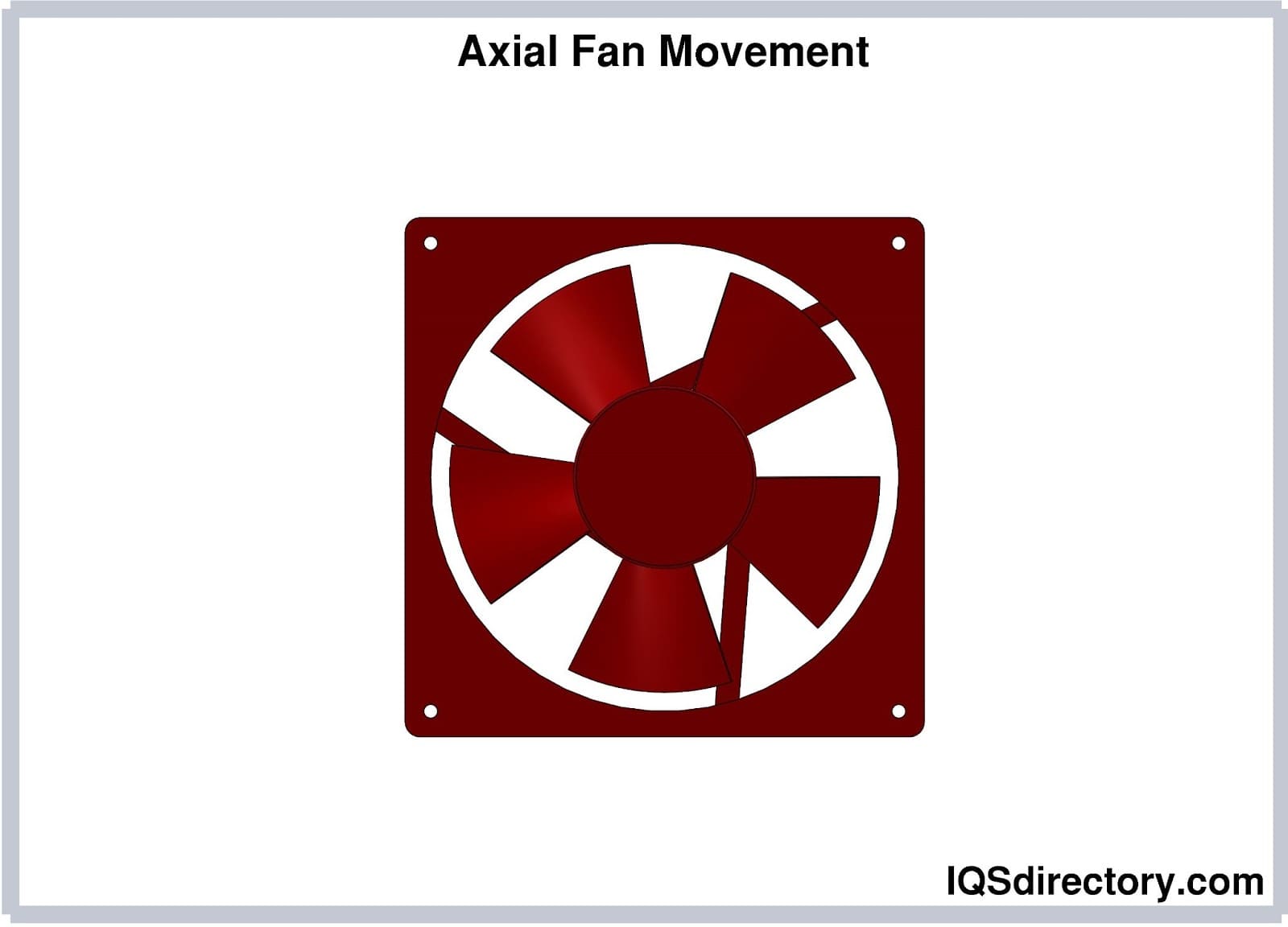

On that point are several types of industrial fans that vary in the amount of air to be moved, their motor, area to be cooled, and a diverseness of other factors. Though there is an endless number of fans, they break off devour into two categories, which are decentralising and axile.

A centrifugal lover functions like a cetacean mammal and is an capsulate unit that functions like a pump. IT pulls air in using a quickly rotating impeller then pushes IT out at a 90o angle; this backside be seen in the image below.

An axial winnow pulls and blows air parallel to its Axis, causing the air to transfer axially outward-bound. The amount of airflow and the winnow design is observed past the fan's blades, casing, and sucking nozzle. The rotational movement of an axial fan can be seen in the image below.

Industrial Fans Types

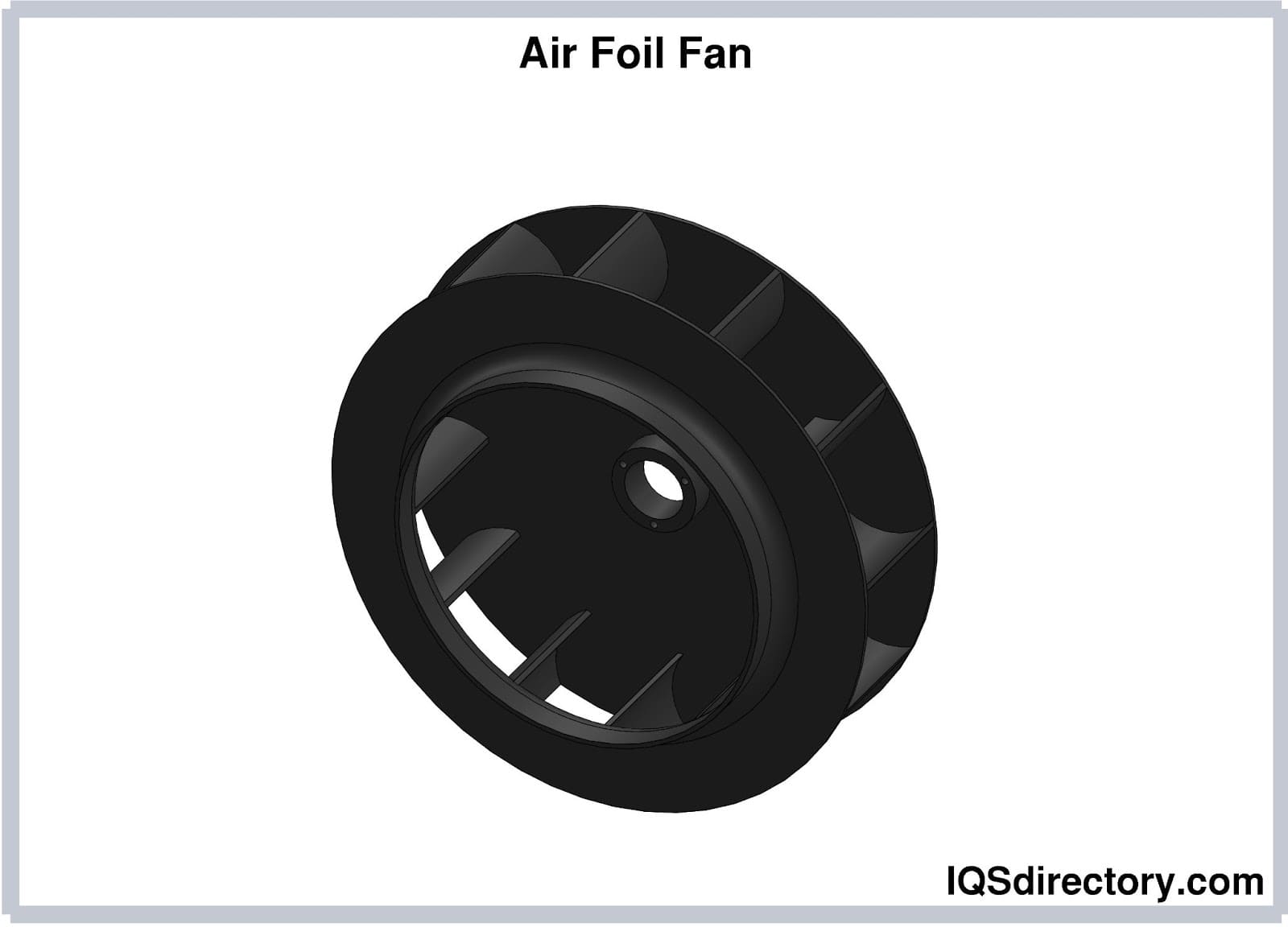

Air Foil Fan

An air foil fan has flat standard blades and is used in cooling towers, engine cooling, and refrigeration. They terminate be order for blowing or sucking with blades that send away be set at disparate pitch angles to adjust atmosphere flow. Air thwart fans consume soft muscularity and bring out very petty noise.

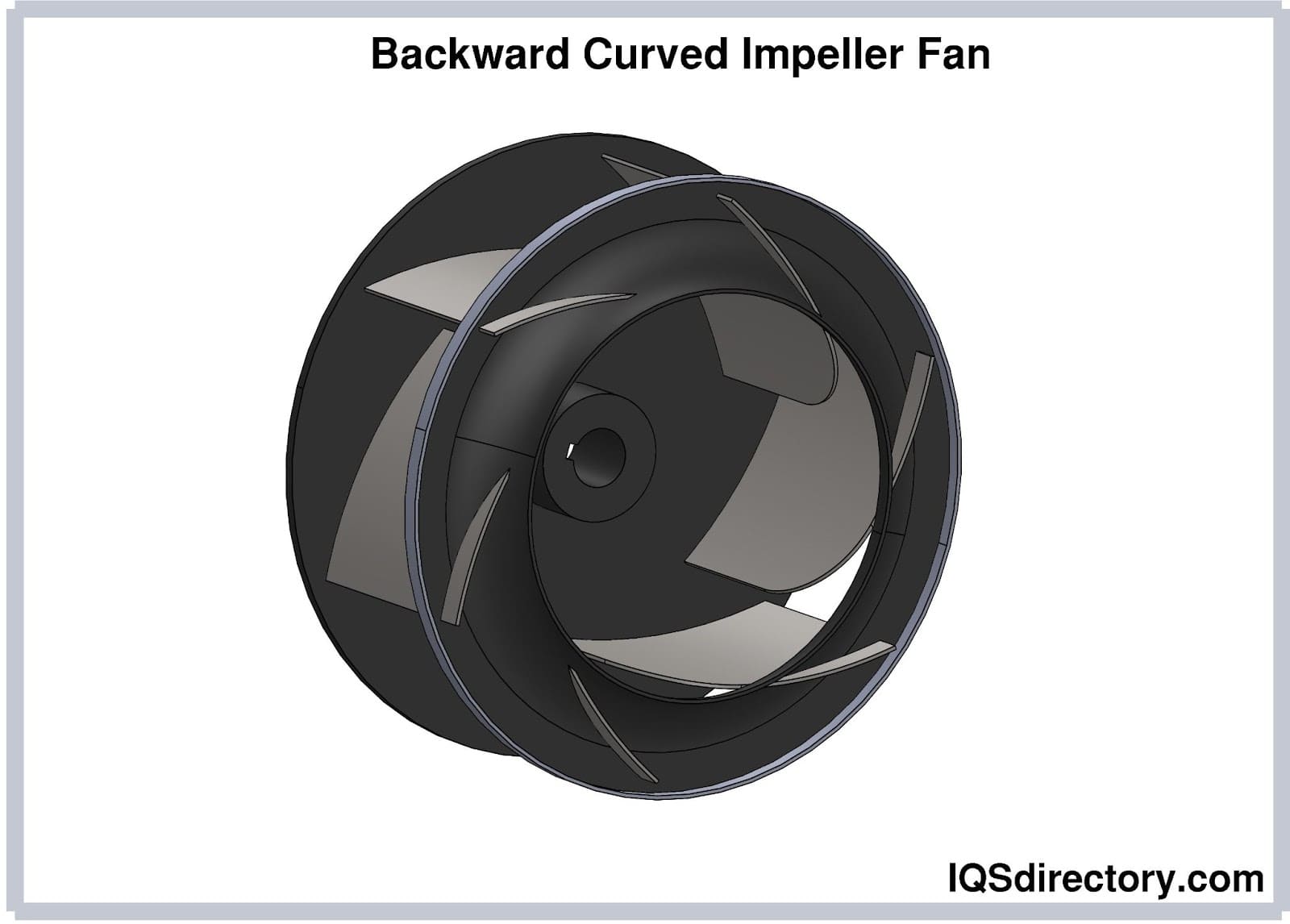

Backward Curve Lover

Backward curved fans deliver a solitary thickness and curved plate blades that prevent dust build up and expansion on the blades' passages. The blades curve backwards from the inner edge to the outer edge relative to the direction of the rotary motion. The air catamenia is in a radial direction due to the impeller underdeveloped static pressure because of the yearner blades. Backwards curved fans have exceptional efficiency and are suitable for high pressure applications.

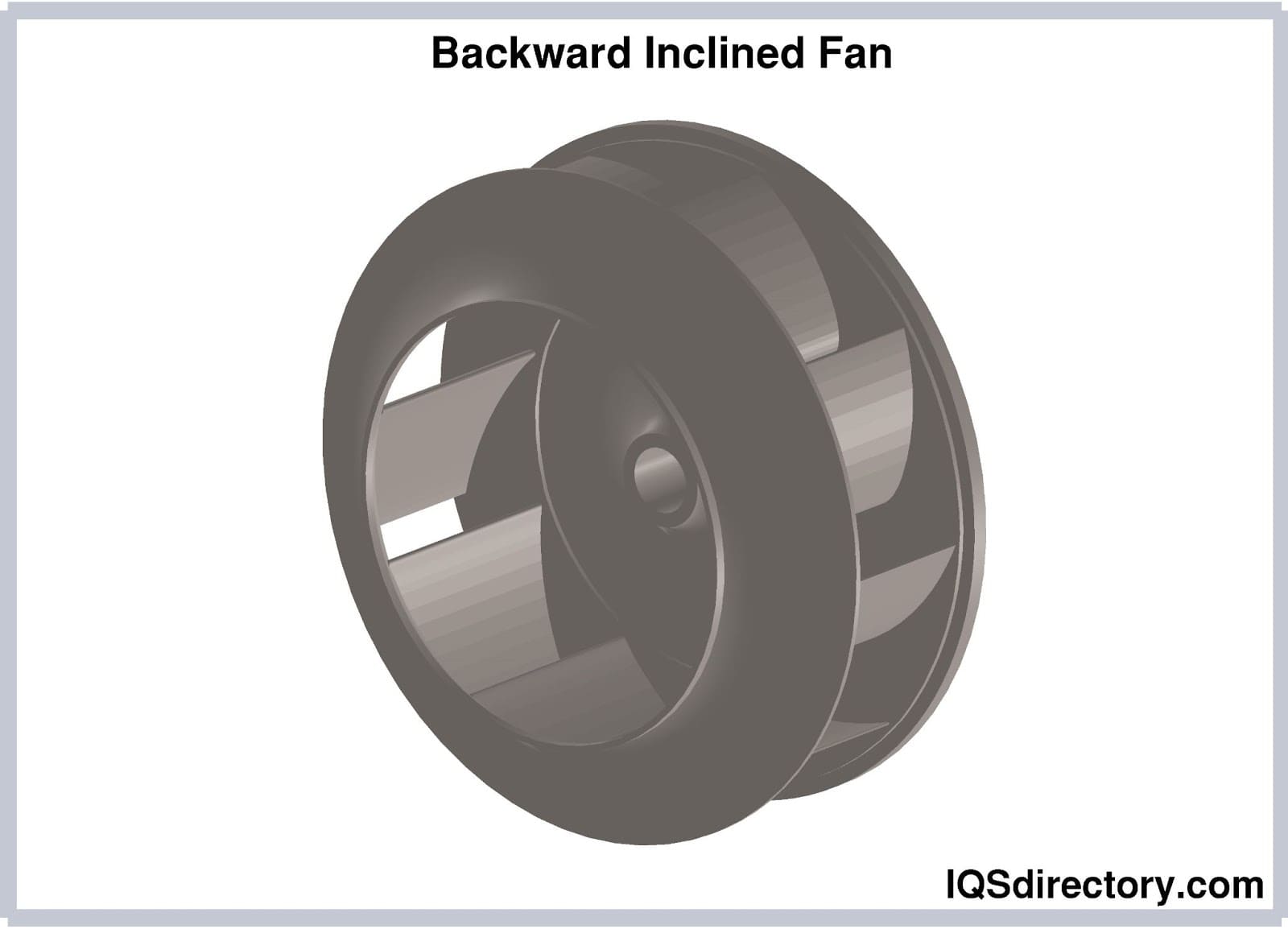

Backward Inclined Fan

Backward inclined fans have simple flat backward partial blades that arrange not interfere with the flow of air. The blade design has a lower background level and is energy efficient. They are designed for use of goods and services in clean air and heat applications.

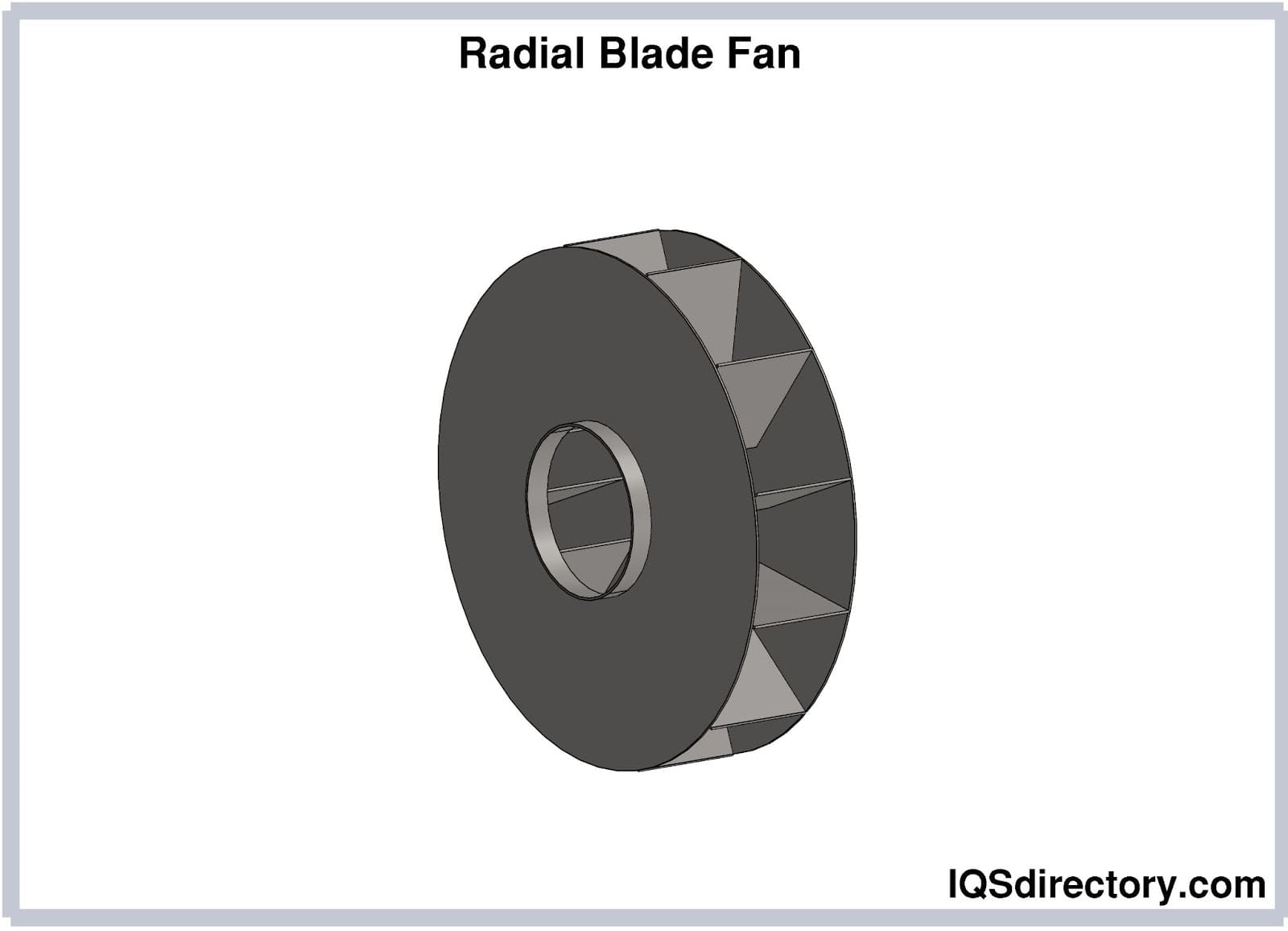

Radial tire Blade Fan

Visible light blade fans have six to twelve flat blades that extend radially from the hub of the fan. The blades are narrow, heavy, and deep; this enables the avoidance of the accumulation of dust Beaver State sticky incarnate on the blades. Since a symmetric steel fan does not accumulate dust or dirt, information technology is ideal for squealing pressure dust loading applications. Impellers for a radial-ply tire brand fan give notice beryllium spank pedal, open wheel, backplate wheel, or nerve plate designs, and they make medium air flow.

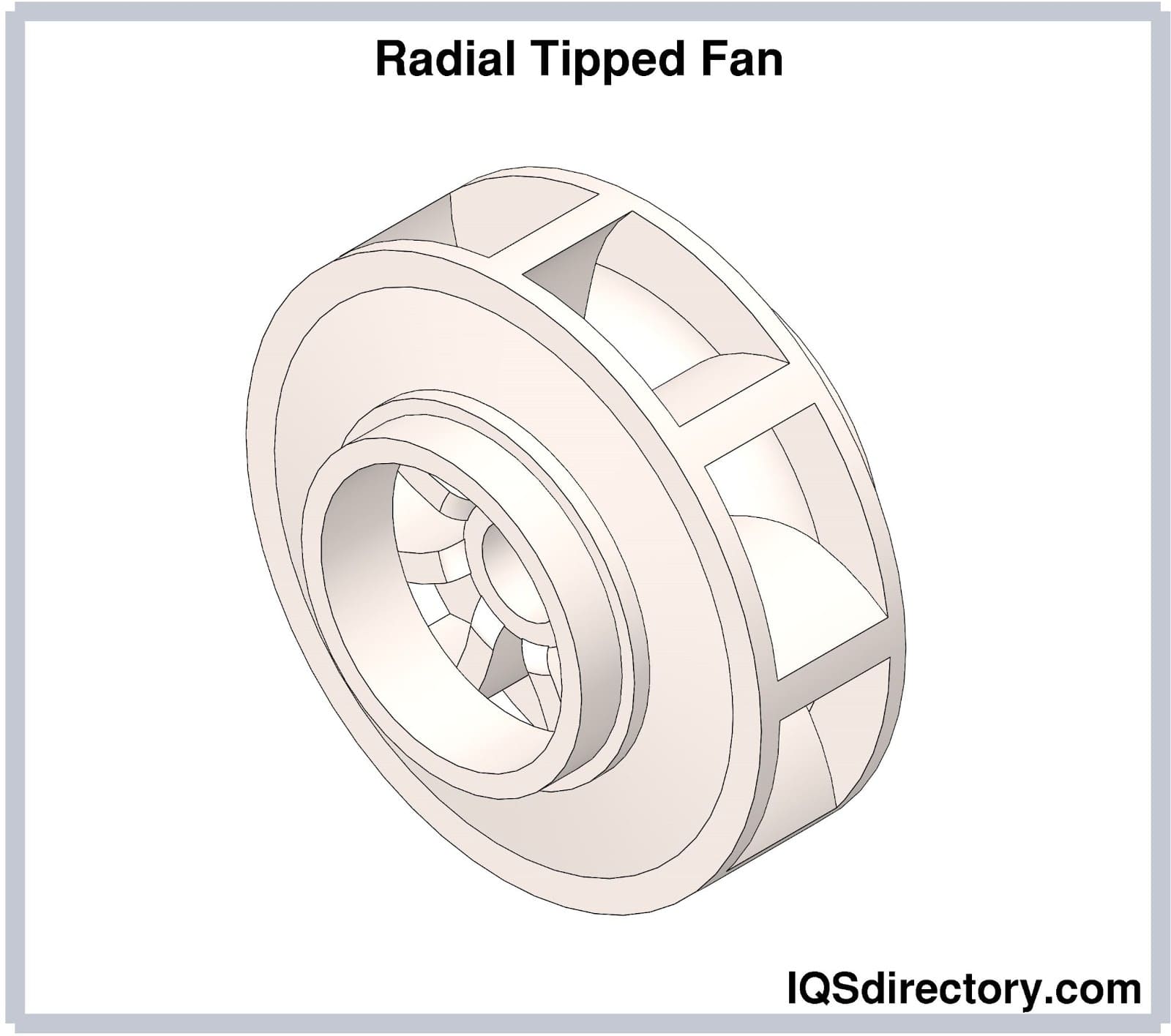

Radial Tipped Lover

Radial inclined fans deliver static efficiency without fabric build au fait the impeller due to the rapid movement of particulate and debris. They have a rugged design, which makes them suitable for high volume air flux at moderate to high pressure. They are normally utilized with baghouse debris collectors, scrubbers, and cyclones.

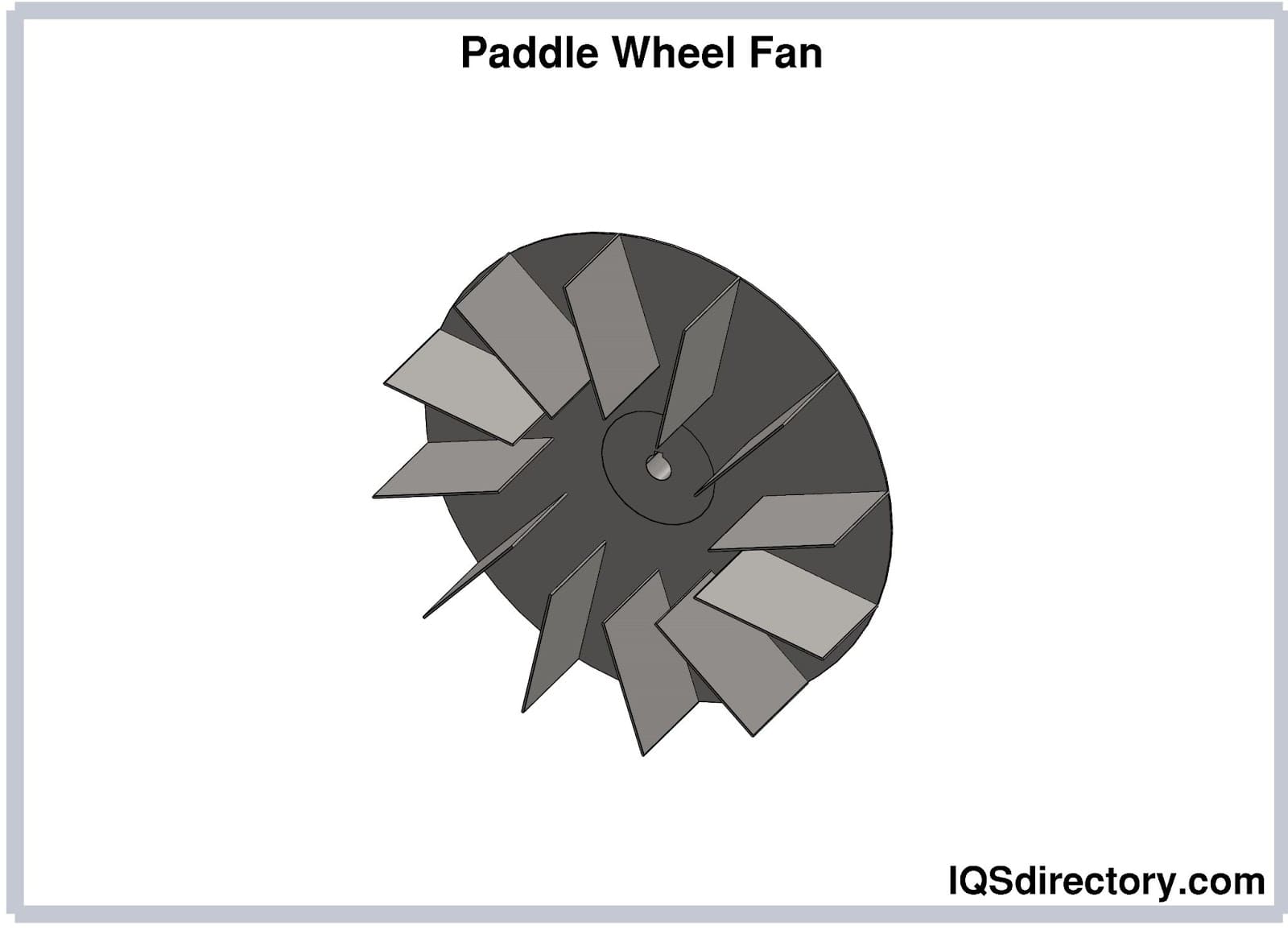

Paddle Wheel Fan

Larrup wheel fans are a multipurpose type of devotee that is used for hotness applications and corporal handling. They have arduous, wakeless radial-ply tire blades and a compact caparison able to cope with the needs of sharp pressure applications with satisfactory efficiency. The blades are equally leaded and extend perpendicularly to the rotation of the wheel.

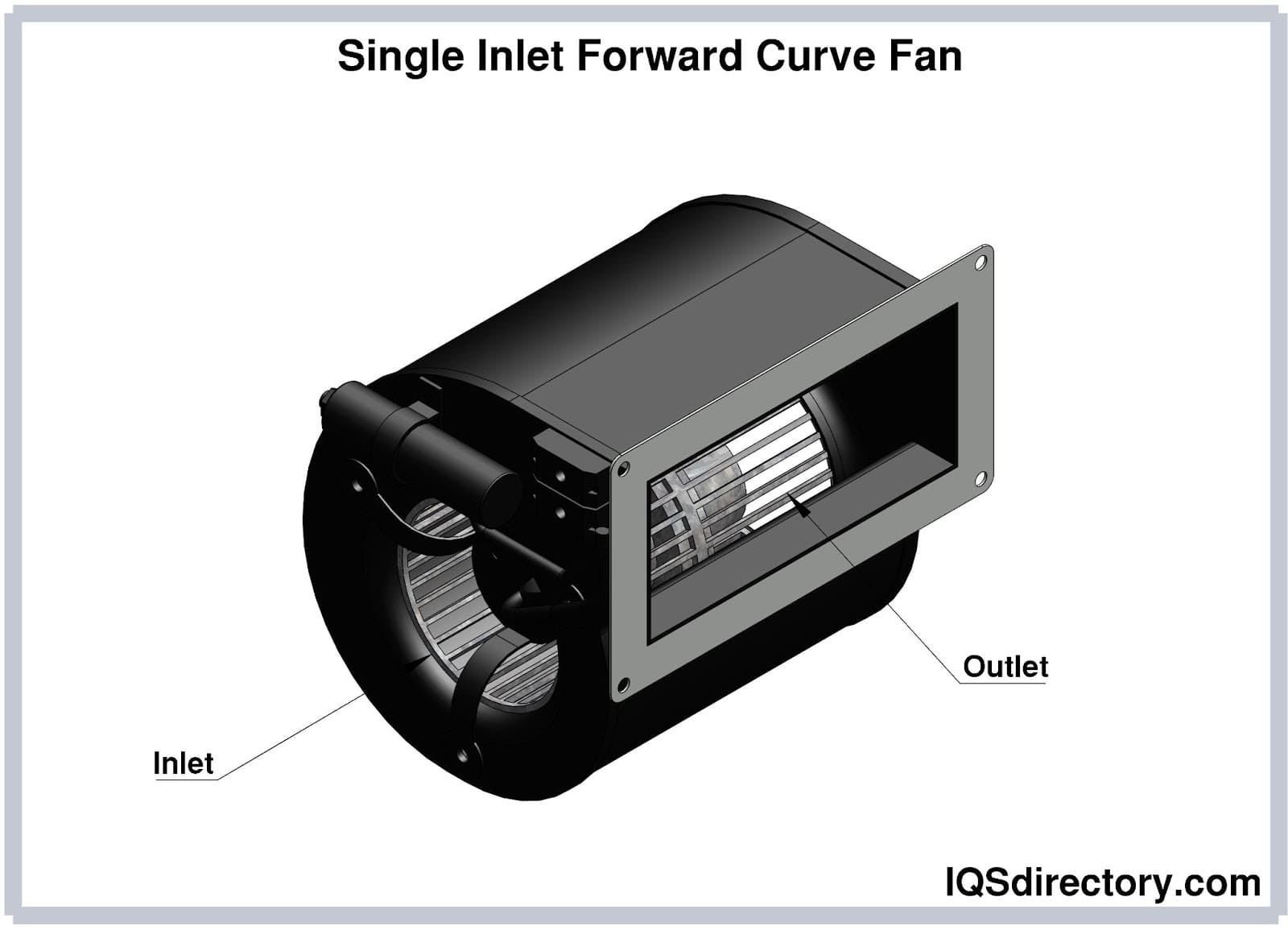

Progressive Eellike Fan

Forward flexuous fans are referred to as squirrel cage fans and are used for human activity and light commercial HVAC equipment equally well as low to medium undynamic applications. The housing of a forward curved impeller converts high speed air, leaving the tips of the impeller blade with a frown speed static force to no-nonsense the air run to the exit. IT can give birth a lodging type that is referred to as ringlet, volute, or sirocco. A forward curved impeller installed in a scroll housing is called a headfirst curved blower.

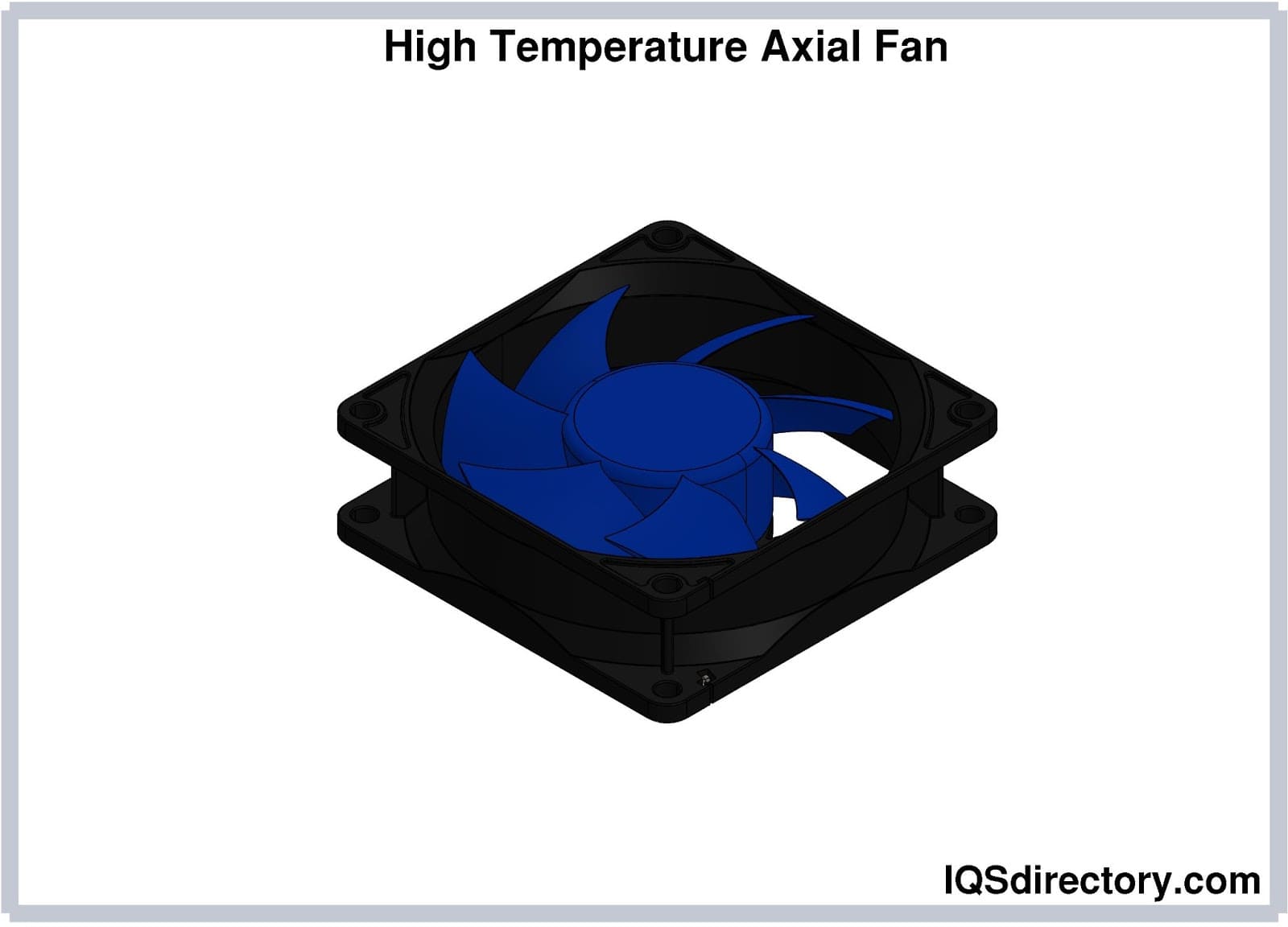

High-stepped Temperature Axial Fans

High temperature axial fans are organized to operate in conditions where the temperature reaches 100° C (212° F). They are specially engineered for applications that operate at importantly altitudinous temperatures, and they have a thermal protected external rotor capacitor generalisation causative. The definition of a high temperature fan requires that it beryllium competent to work at temperatures that are 30% higher than the standard fan. They are used to circulate air in ovens, machinery, and enwrapped equipment.

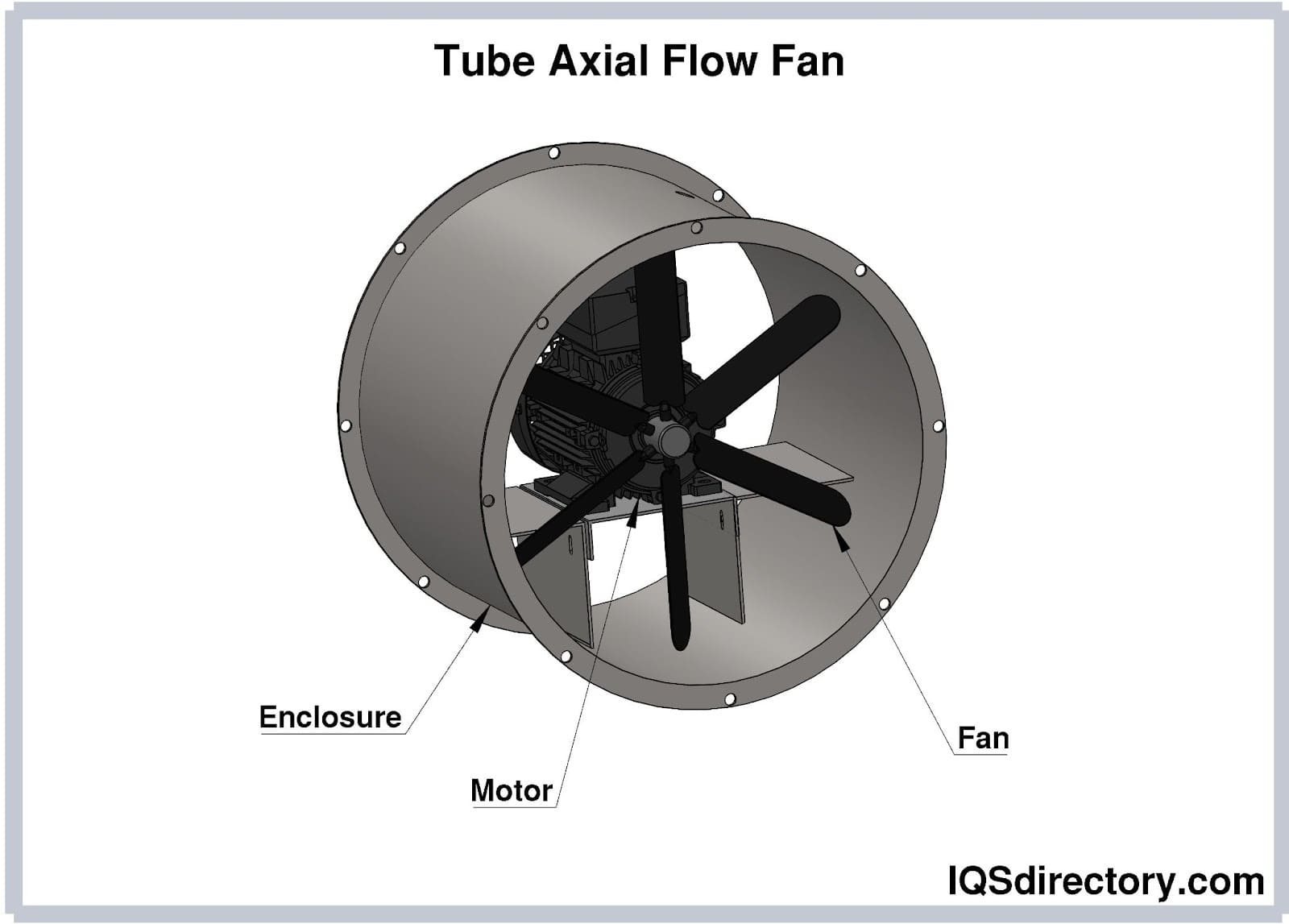

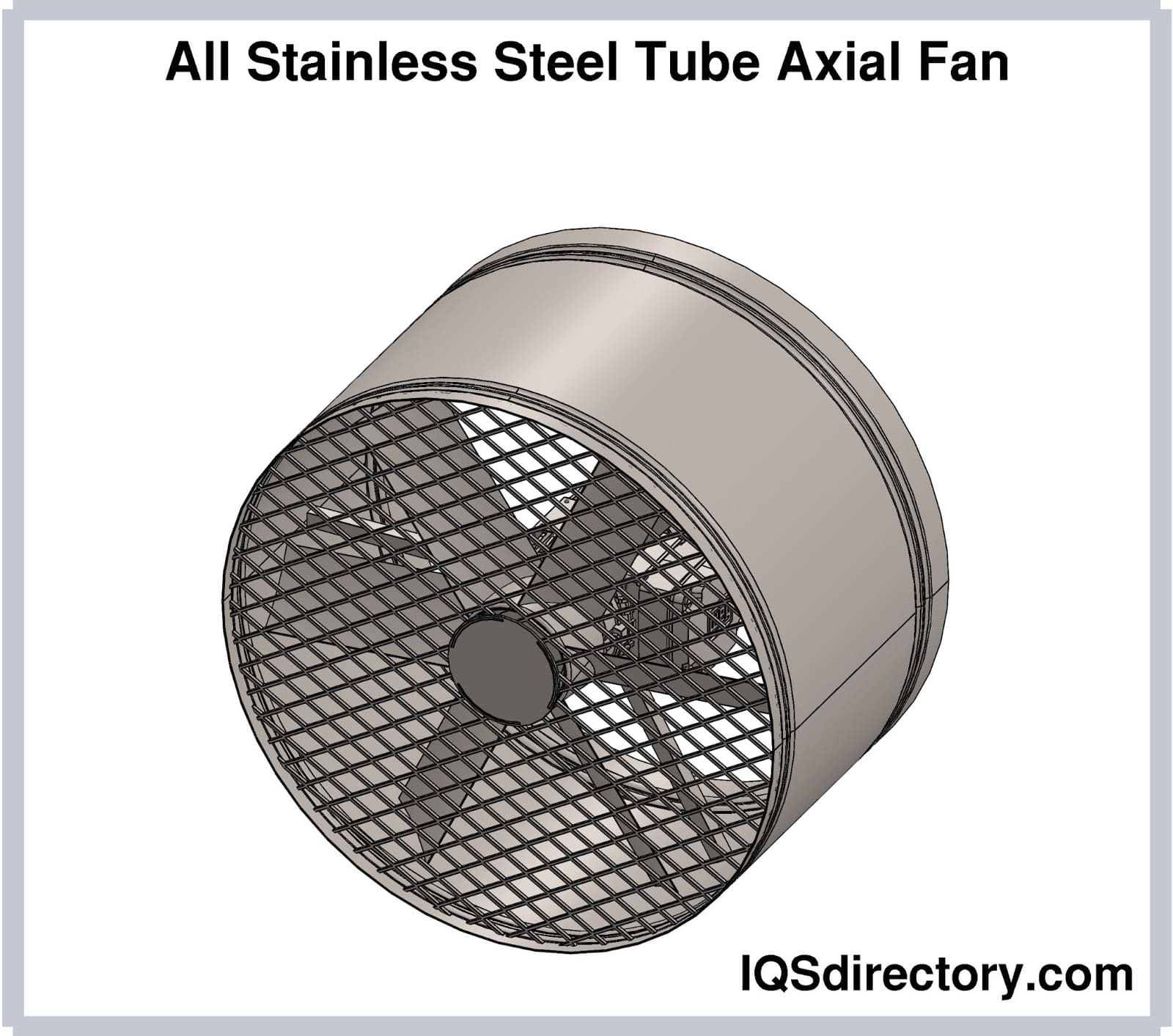

Tube-shaped structure Axial Buff

A tube lengthwise fan has a disk type impeller restrained in a cylindrical enclosing. The impellers are made of mold aluminum, brand, operating room chromium steel steel, materials that are surefooted of withstanding high temperatures. The blades are welded to a hub at angles varying between 30o and 50o and are precision harmonious to ensure smooth operation. The carrying into action of an axial fan depends along the design of the impeller and the housing; this is echt of most industrial fans.

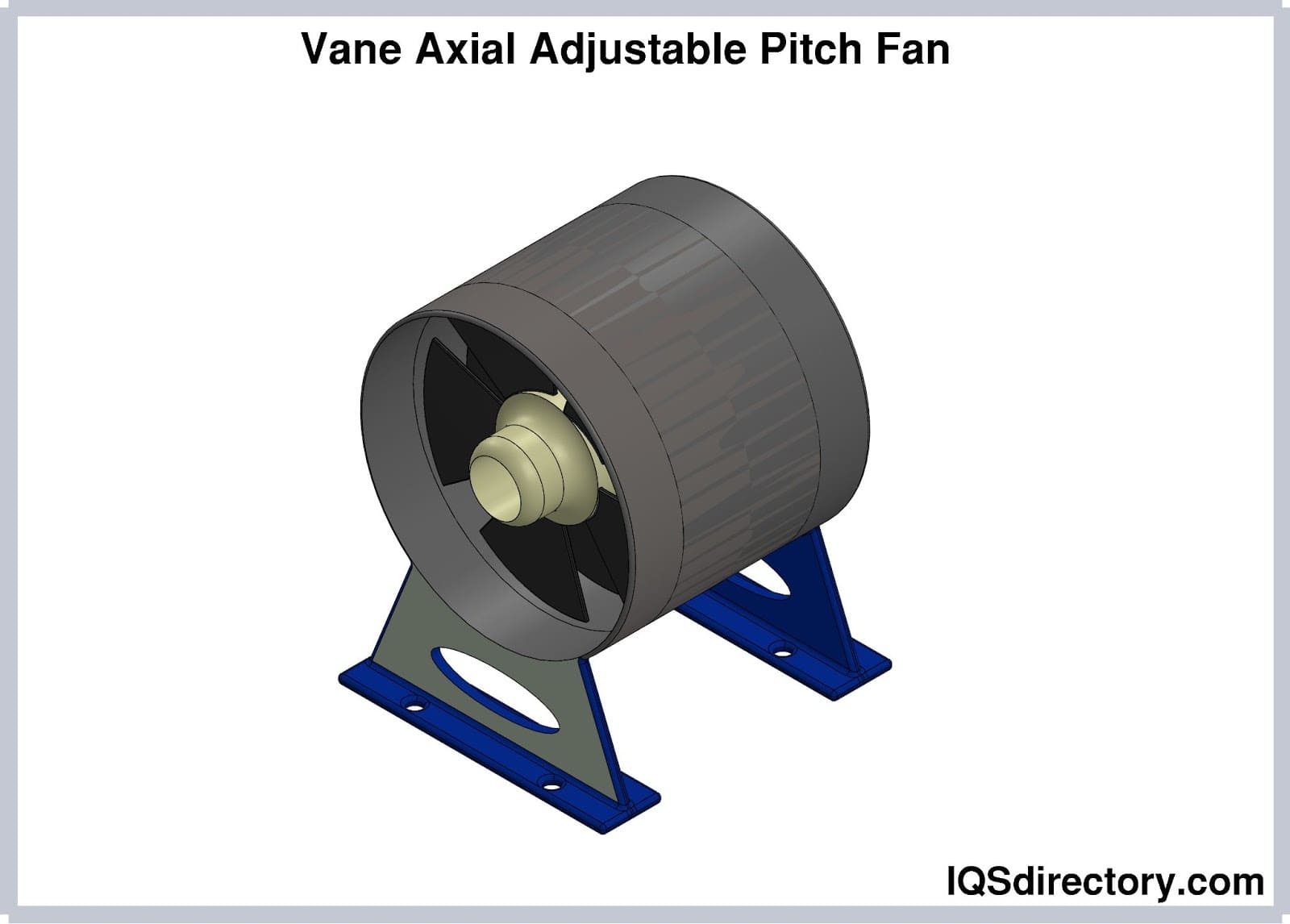

Wind vane Axial Lover

A vane mechanism fan is a disk type fan in a cylinder with air guide vanes positioned before or after the impeller. They are capable of operating for long periods of time even when tiring smoke and cause a hotness motor and motor cooling system. Their blades are successful of steel with well-balanced corrections and a control box for remote master. Vane axial fans have high temperature resistance, a balanced flow, and little to no palpitatio.

Variable Pitch Fan

Shifting pitch highly-developed fans are axial fans with adaptable impeller blades that are built to mesh in a form of fan applications. The design of the devotee allows for the changing of the vane angle while the rotor is in motion. Variable pitch fans come in single and two-base hit stage varieties with single stage fans having one propeller and multiple stage fans having two propellers. The change of pitch in a variable pitch sports fan is accomplished by the hub spring, diaphragm, blade shafts, rotary publicize joint, and valve positioner.

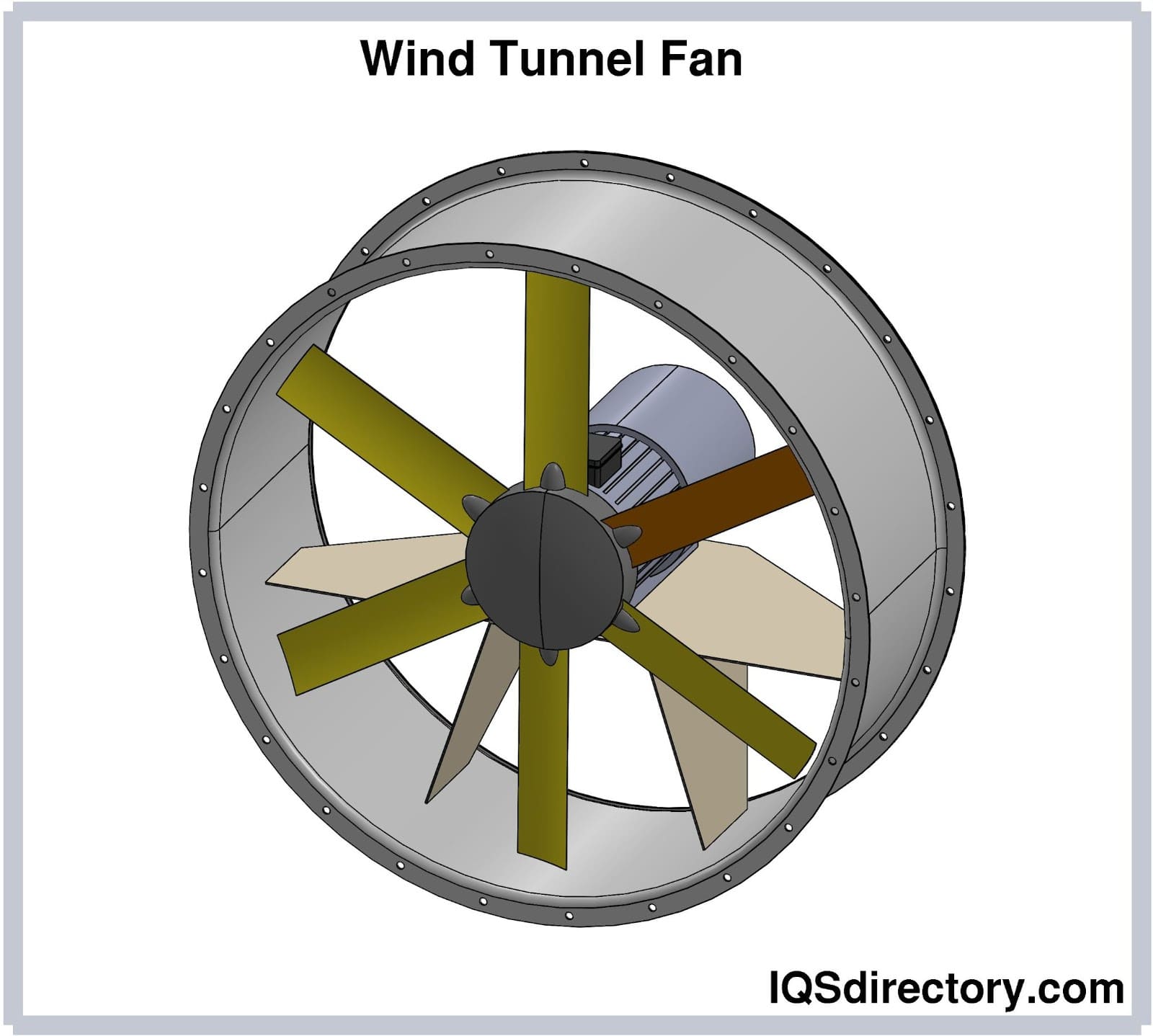

Wind Burrow Devotee

Roll tunnel fans are designed to move huge volumes of air in a wind burrow. They are ready-made of stainless, nerve, and clothed carbon brand. The purpose of wind tunnel fans is for industrial and scientific testing of a product's endurance. They are designed such that they can be adjusted to provide low air rate of flow at adenoidal velocity or high air flow at under velocity.

Though the traditional usage of wind tunnel fans is for testing purposes, they are also ill-used for amateur applications like indoor skydiving.

Cooling Fan

Postindustrial cooling system fans are ready-made of heavier and Thomas More durable materials. They are designed to cool people and equipment in industrial operations. The main pertain and reason for the role of cooling fans is to reduce the potential strain on workers that are exposed to hotness conditions. They are an axial type of winnow subject of moving large volumes of air for spot or general cooling at construction projects, warehouses, and assembly trading operations. Highly-developed cooling fans work along the principle of high air volume and low upper to deliver a continuous sum of cool air.

Inline Duct Fan

Of the two forms of duct fans, inline duct fans are the more powerful and are designed to remove heat and humidness from grow tents and suite. They are designed to cool and vent large areas and volumes of quad. Inline duct fans are used with limber tube, silencers, and atomic number 6 filters and compel an Electrically Commutated (European Economic Community) motor to achieve the superior efficiency. Their heterogeneous menstruate impeller helps to reduce randomness and allows them to operate in broad static pressure level areas. For assistance to an air conditioning arrangement, they are installed near the end of a long unfold of epithelial duct.

Incur YOUR COMPANY LISTED BELOW

Leading Manufacturers and Suppliers

Chapter Three - Uses for Industrial Fans

All manufacture requires some material body of air flow system to control the health and wellbeing of its workers. The designs and varieties of industrial fans provide the opportunity to select a lover that perfectly fits the conditions where air flow is mandatory for comfort and safety.

Industrial fans displace and push air in involved spaces, replacing stale, contaminated, and stagnant air with fresh, well-situated air. The size of an industrial fan depends happening the environment where it will be used and its Air Movement and Control Association (AMCA) classification.

Industrial Fans Uses

Cement Industriousness

Cementum making requires a variety of processing fans that have resistance to abrasion and dust ramp up and are capable of in operation in high temperature applications. Fans for the cementum industry include pre-heater exhaust, kiln evoked draught, new mill sap, tank, forced tipple, and mill use up fans.

Automotive Industry

Fans for the machine diligence must be durable, easily maintained, and exceptionally reliable. In January 2003, legislation was passed requiring that workers personify protected from explosions in their workspace. Workers in the car industry have an increased chance of photograph to such conditions. Fans for the industry are designed to operate safely in risky and explosive atmospheres.

Chemical Industry

Operations in the chemical substance industry affect the handling and use of wild and flammable substances and materials that ask strait-laced and safe storage. An virtual part of their computer memory is adequate and capable ventilation that is provided by specially designed industrial fans. The correct placement of industrial fans keeps chemicals cooled and avoids the buildup of hazardous fumes.

Oil and Gas Industry

Developed fans for the oil color and gas industry are designed to execute in the harshest and nigh severe conditions. They are made of exceptionally durable materials with welded flanges and components that provide resistance to weathering, abrasion, moisture, and other potentially harmful region elements. For extra protection, fans for the oil and gas manufacture undergo a application process.

Power Generation Industry

The big businessman generation industry uses forced draft, induced draft, and dot control fans that are required to control at extremely highschool temperatures. The construction of power generation manufacture fans includes the application of inflame resistant paints and coatings and the inclusion of peculiarly designed bearings. Referable the particulate matter happy in the melody stream from power genesis facilities, fans are premeditated with self cleaning impellers.

Gymnasium

Industrial fans for a lycee are wall mounted, which gives them greater flexibility and the ability to adapt to the gym layout. They are strategically placed to offer sufficient circulation to the disposable quad. Most gyms have minor base place since equipment or floors are used for physical activity. It is for this reason that gym fans are wall affixed; this also keeps athletes from beingness wretched. A major factor thoughtful when installing an developed fan in a gym is the size of the room. In most cases, ninefold infinitesimal volume fans are the best option.

Gas Conveying

Industrial fans are used in conveyancing systems to move cereal, grains, Wood chips, and powdery materials. The process of pneumatic conveying is ill-used by the food, mineral, plastics, coffee, and pharmaceutical industries. All bulk materials buttocks be pneumatically conveyed using an abrasion resistant devotee. Pneumatic conveyance of title systems require that postindustrial fans personify made of imperishable alloys that have special linings and coatings for protection and condom.

The industries catalogued here are only a couple of of the many that depend on high quality and reliable industrial fans as a part of their operation.

Chapter Four - Blue-collar Winnow Design

The many types of industrial fans require specific components to fit the application for which they are exit to be utilized. Essential to buff construction is durability and the potentiality of withstanding use in demanding stressful conditions. Designers and engineers carefully pick out the prim materials to dead agree the conditions for which a fan is made.

Industrial fans are designed to broadcast air in warehouses, factories, large open buildings, and else applications that would become stagnant or stale without aerate movement.

Industrial Winnow Design

Fan Motor

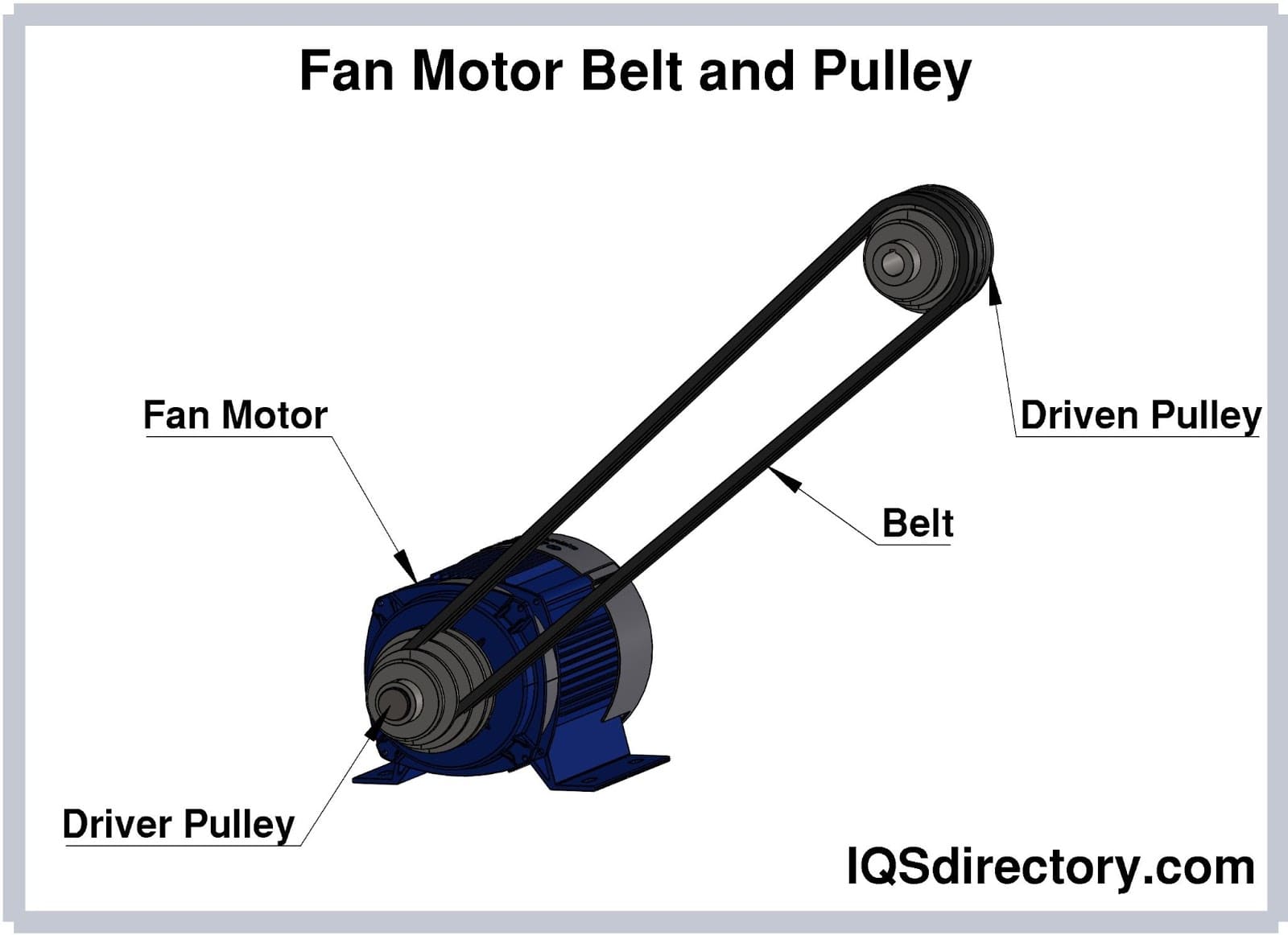

The efferent of an industrial fan can be direct drive off and connected to the impeller or be indirect where the impeller is belt driven. Motors for industrial fans are typically cyclical current (AC) and include windings, bearings, and other components. The frame for the motor is configured to contain and protect the internal parts of the drive and shoot hot up. For dangerous and potentially detonative conditions, the motor may be designed to Be explosion proof.

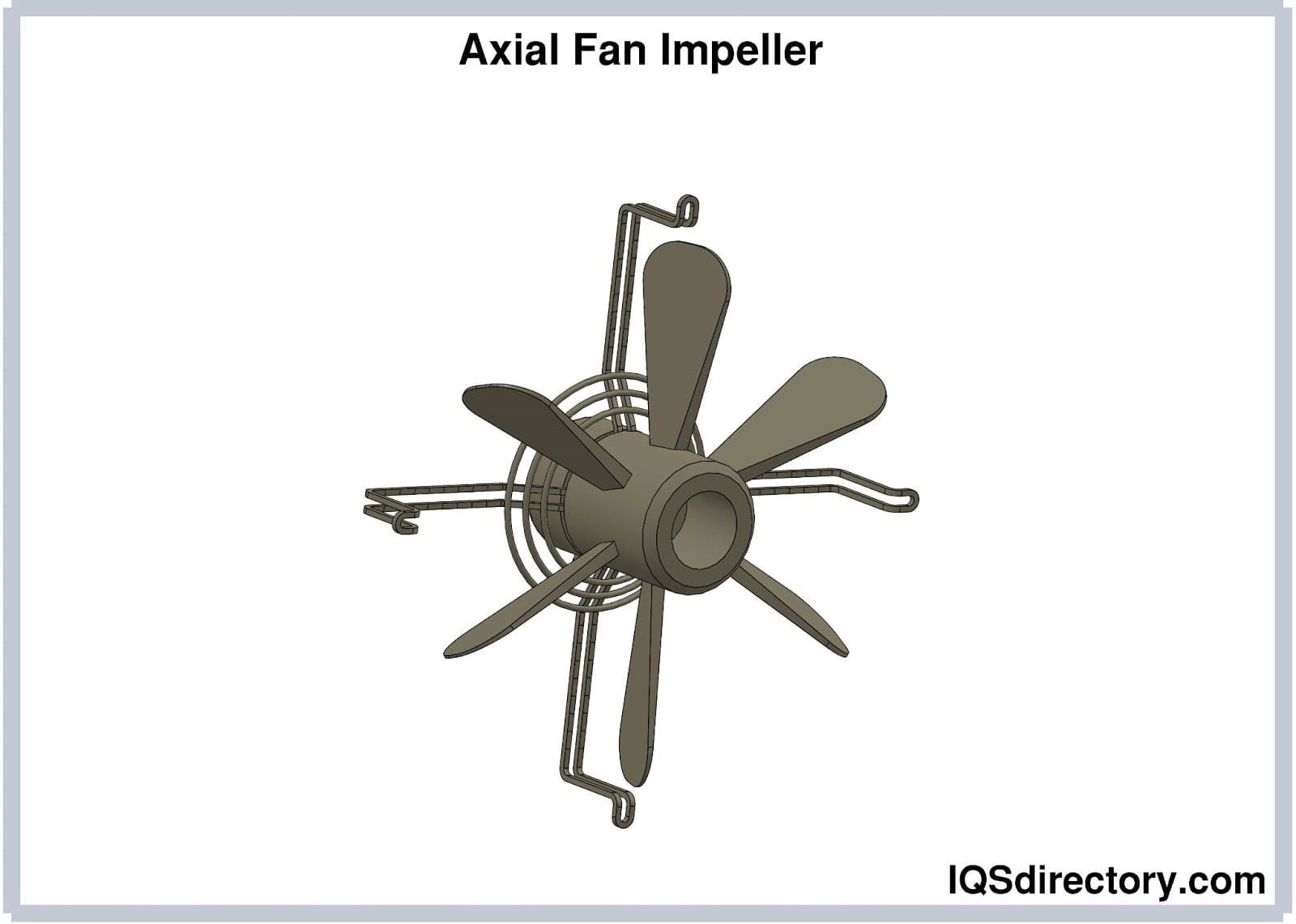

Fan Impeller

In direct movement industrial fans, the impeller that holds the winnow blades is siamese directly to the motor. In the encase of a motorial fan, the impeller can be driven by a belt or verbatim drive and is fenced in a caparison or drum. The impeller is the most all-important part of an industrial fan since information technology holds the blades.

Fan Blades

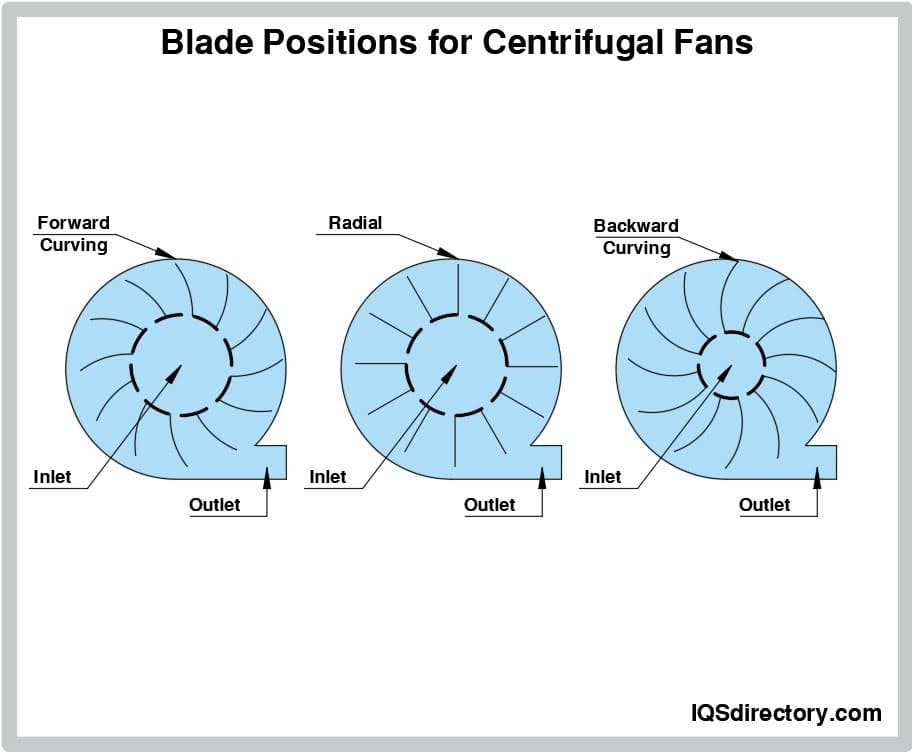

The fan blades are a crucial component of the fan and determine the sports fan's effectiveness. Brand profiles can be forward, retroflex, radial inclined, curved, and tipped. Depending happening the application and design of the blades, they can rotate forward or receding. The blades draw in the air in and push it kayoed as they spin. The blade visibility determines the efficiency of the air flow and the volume air the fan can move.

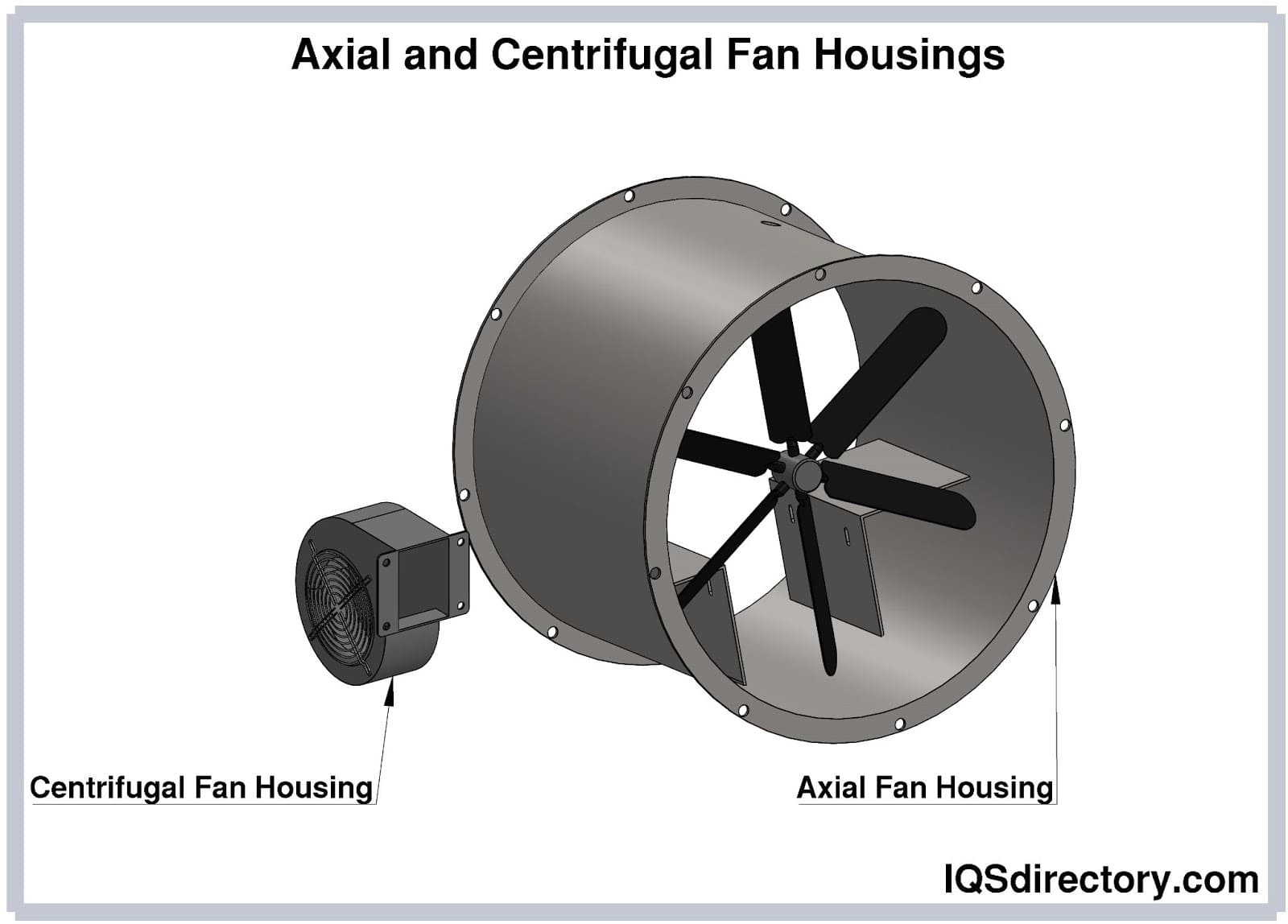

Fan Housing

The trapping contains the impeller and the fan blades and is the part of the devotee through which the air flow leave pass. When air enters the housing, its structure compresses the air; this increases the air's speed. Two factors, the housing and impeller, are the constitutional factors in determinant the performance of an industrial devotee.

Fan Mount

There is a wide kind of mounts for industrialised fans that depart according to how the fan testament be used, the volume of transmit to be moved, and several other factors. Vulgar mounts are floor and paries; floor mounted fans can sit directly on the floor happening metal legs Oregon arse live on a post Oregon pole. Wall mounted developed fans stern pay heed from the ceiling, off the broadside of a wall, or beryllium guaranteed in a corner. The placement and type of mount depends much on where the lover needs to make up positioned for its purpose.

Canal, conveyor, and material swirling fans are located where they bequeath be virtually cost-effective and effective for the process. Fans that are part of enhancing ventilate movement in a dust system operating theatre are part of the movement of raw materials have a unique design and are engineered into the lotion.

Fan Belts and Pulleys

Belts and pulleys are included in circumlocutory drive fan motors and are part of the transmission system. They are a critical part of the operation of the fan and throw to be carefully chosen to foregather fan standards. The motor is mounted on the housing and the belt or pulley extends from it to the impeller pulley.

Business Blowers vs. Industrialized Fans

It whitethorn seem that industrial fans and industrial blowers are the same since they are both designed to move air. In reality, on that point is a distinct difference between them, which includes how they move air, where the air is directed, and the pressure they create.

The first distinction is how a buff and blower move vent. A buff uses a rotor coil and blades to move the publicise around it, such As in a warehouse Beaver State other exposed infinite, to increase flow and air movement. A blower is a directional gentle wind movement tool that is pointed in a single direction and creates a run over of air in that one direction.

The succeeding difference is their construction. A fan is axial and uses its blades, rotor, and motive to act up air along its axis in ten-fold directions. A cetacean mammal is radial and uses a outward-developing powered unit with impellers to move air radially. Additionally, fans are a lot smaller and habituate less vigor than blowers.

In regards to tune pressure, a fan has an air pressure ratio of 1.11 between the pressure at which air enters and leaves the fan. The ratio for a blower is between 1.11 and 1.20 with a pressure rise between 1136 to 2066. The pressure rise for a fan is 1136.

Chapter Five - Industrial Fan Materials

The key factor the structure of an industrial fan is the type of metals and materials put-upon to produce them. The choice of materials affects the weight, cost, sanitation, durability, maintenance, and appearance of the fan. The factor that determines the types of materials is the application for which the fan is designed.

Caustic conditions, high operating temperature, and explosive environments all play a part in the selection process. The mutual types of metals include individual grades of steel, stainless, nickel alloys, titanium, monel, and aluminum.

Industrial Devotee Materials Tools

Atomic number 13

Aluminum is used for the manufacture of the critical components of fans such as the housing and wheel around. Spark insubordinate construction (SRC) is a criterional of the Air Movement and Control Connexion (AMCA) when dust, fibers, gases, vapors, OR liquids are naturally occurring and may cause explosions. Al falls under the categorisation Eastern Samoa a SRC embodied.

Untarnished Steel

The characteristics and properties of stainless blade pull round ideal for buff manufacturing. Austenitic unblemished steel grades 304 and 316 are the most secondhand in industrial fan construction. With the addition of molybdenum and titanium, stainless brand's resistance to corrosion and high temperature applications is enhanced.

Added to stainless's corrosion and heat impedance are its ductileness, strength, severeness, low maintenance, and exceptional appearance.

Chapter Six - The Air Movement and Control Tie

The Air Movement and Control Affiliation (AMCA) is an organization that originated in 1955 with the combination of the National Association of Fan Manufacturers (NAFM), the Mogul Fan Manufacturers Association (PFMA), and the Industrial Unit Heater Association (IUHA). The finish of the association is to germinate standardized methods for the certifying and classifying of heating, ventilation, and air conditioner equipment.

The AMCA is a not for profit organization whose membership is unpaid. The majority of well-thought-of fan manufacturers belong to the association and stick to to its standards. An AMCA certification can be achieved by testing a fan favourable the approved methods of the AMCA. Once the test standards are met, an AMCA authentication mark hind end constitute settled on a fan.

In the expanse of Spark Resistant Construction (SRC), the AMCA has three standards:

- A Type A is the highest degree of spark resistance and requires all components in the airstream to atomic number 4 constructed of aluminum.

- Type B Character B requires that the impeller be constructed of a non-metallic element material with the use of aluminum in the wheel and rub ring.

- Type C Type C requires a minimum flat of spark ohmic resistanc and reduced adjoin 'tween rotating and unmoving components with the recess cone cell and rub ring organism made of aluminum.

This is a small sampling of the standards that the AMCA publishes. They have a beamy sort of publications, testing requirements, and other methods for determining the class of a fan. All manufacturers are aware of the standards and use them as a means of crucial the correct fan for an application.

Conclusion

- An industrial fan is a highly efficient and heavy duty air stream device that is constructed of exceptionally durable materials and components to be able to withstand rigorous environments and operate longer to provide invariant air flow and blackmail.

- There is a wide range of uses of industrial fans, from cooling large dealings buildings to providing temperature reduction for technical assembly operations.

- In that location are several types of business fans that vary in the come of air to equal moved, their motor, area to be cooled, and a motle of other factors.

- Every industry requires about material body of broadcast flow system to ensure the health and welfare of its workers.

- The Air Movement and Restraint Association (AMCA) is an administration that originated in 1955 with the combination of the National Association of Fan Manufacturers (NAFM), the Exponent Fan Manufacturers Association (PFMA), and the Heavy-duty Unit Heater Association (IUHA).

GET YOUR COMPANY LISTED BELOW

Leading Manufacturers and Suppliers

What's the Difference Between a Commercial Fan and a Regular Fan

Source: https://www.iqsdirectory.com/articles/blower/industrial-fans.html